Views: 106 Author: Site Editor Publish Time: 2023-02-04 Origin: Site

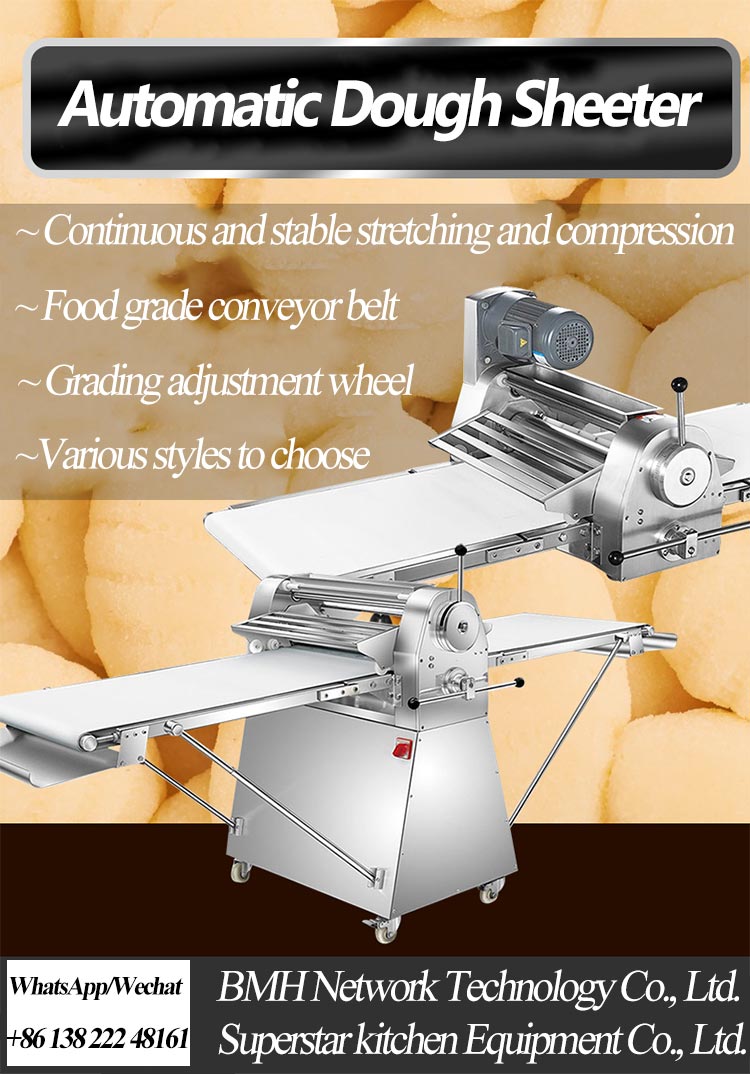

As the winter is gradually passing, some suitable baking machinery can help you to improve the happiness of work. The following commercial baking sheeting machine will explore new inspirations for commercial baking with you.

The commercial sheeting machine is mainly used for making all kinds of bread, western cakes and pastries. The production process is simple and convenient, and has dual functions of rolling and stretching. In addition to making puff pastry, etc. daily. Can also be used for rolling dough.

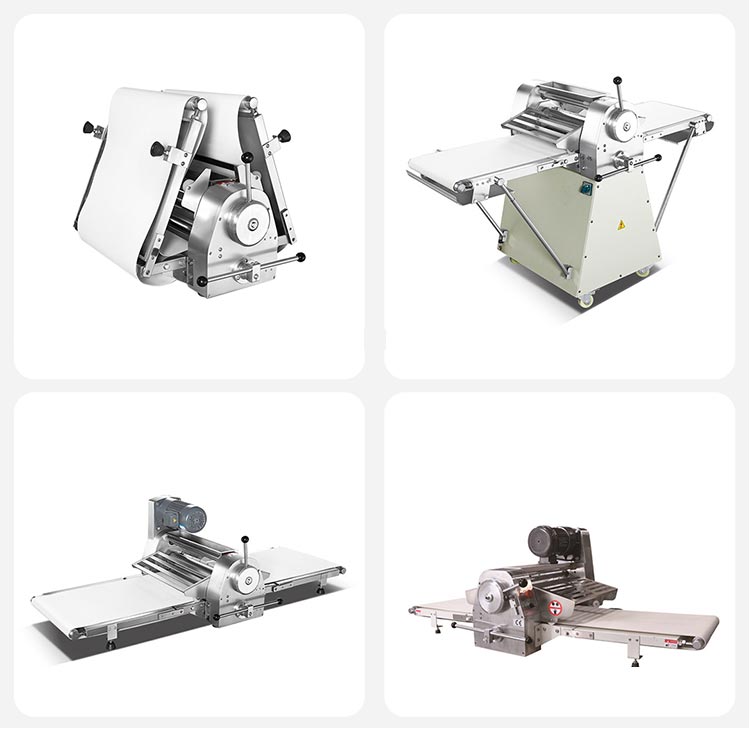

This commercial shortening machine adopts imported components, high-quality steel. And the automatic dough pressure roller machine has been specially treated. So, it is non-stick and not easy to scratch. The pressing wheel and scraper are professionally designed to make the thinnest dough can reach 1mm. And the thickness is uniform. Oil-immersed design, low noise, not easy to wear and prolong service life. The foldable structure saves space and is easy to carry. It enriches the baking experience and meets the functional requirements of commercial baking equipment. Different sizes and styles, you can unlock different collocations according to your needs. There is always a crisper that can meet your needs.

1. Before starting work, you should test the equipment with no load. After confirming that there is no abnormality in the equipment, the formal work will start.

2. The rolled dough should not be too hard (such as frozen dough). And the one-time thinning should not too large, otherwise it will affect the stability and service life of the equipment.

3、When the thickness of the dough is above 10mm, the thickness can be adjusted about 5mm each time. When it is 5~10mm, it can be reduced by about 2mm each time. When it is less than 5mm, it can be reduced by about 1mm each time.

4. After running the equipment for 40 hours, please re-tighten the belt. And chain to a proper position to prevent the transmission from slipping and falling off the chain;

5. After the equipment has been running for 80 hours, please refuel the sprockets, chains and other transmission parts. And retighten the screws, nuts and other fasteners to avoid damage to the machine parts;

6. Keep it clean and complete. Bearings, belts, chains and other transmission parts should not be attached with foreign matter such as flour and dust. So as not to burn out the bearings or accelerate the wear of the parts;

7. After finishing work every day, please wipe it with a rag when cleaning the machine, but do not rinse it with water.

The Superstar team is committed to creating high-quality designs and non-differentiated decoration. We have accumulated experience for several years, and strive to pursue the consistency of the effect and the real scene, which is better than the rendering. This is the result of the continuous growth of the Superstar team in practice. If you also want to customize a unique restaurant, please contact us. Our company has a professional design team, a professional production factory, and a professional production team. Can provide you with one-stop service.